About Us

For over 45 years, Semi-Bulk has designed and manufactured modular engineered process solutions

involving powder handling and powder-liquid mixing systems for manufacturers of beverage, dairy, food, and industrial

products. Semi-Bulk competes on its mixing technology, engineering expertise, and ability to support

powder handling and powder liquid mixing applications.

Mission & Vision

Mission

Our brand framework consists of our mission, vision, and values. Just like our team, each of these elements works together to create an experience that is bigger and better. Our brand framework is authentic and built from the ground up. The framework is intentional and woven together with our team and our customers in mind.

Vision

Develop and provide the path for growth for every person and organization we work with.

Core Values

Teamwork

Hustle

Elite

Humble Confidence

Driven Yet Fun

Core Products & Services

Semi-Bulk Systems competes on its mixing technology, engineering expertise, and ability to support powder handling and powder liquid mixing applications. Our customers include the following markets and applications:

- Beverage – Brewing / Nutritional / RTD / Sport & Energy

- Dairy – Cheese, Cultured Products / Frozen Desserts

- Food – Confectionary / Dressings & Sauces / Food Ingredients / Meats

- Sugar Liquefication

- Health & Beauty

- Mining – Oil / Gas – Fracking

- Paint – Pigments / Thickeners

- Paper

- Pet Care

- Power (Coal, Marine)- FGD / Hg Removal / Nox Reduction

- Chemical / Various Industrial

Our History

Origin

It was in the development of the Wildfire Chemical Business that Mr. Handleman designed and patented the initial Ejector Mixer Slurry Unit and the precursor to the Air-Pallet® Container. The development of the Ejector Mixer and the shipping container with the air membrane in the base made it possible for Monsanto to offer a fire retardant chemical in the form of a dry powder and rapidly convert the powder into a solution to be pumped aboard airplanes to bomb forest fires and minimize the impact on the environment. This technology continues to be the primary process support for fighting forest fires in a number of world areas.

1975-1995 – The Early Years – SBS 1.0

The company produced a full line of products including Air-Pallet® Containers in round, rectangular and mini configurations; Industrial Air-Cone® Hoppers; and fill and unload units and systems for APC handling. These products were used in a variety of chemical and industrial industries like PVC, printing ink, chemicals and filter aids.

1975 – 1979:

1979-1994: The Company moved into a new 20,000 square-foot manufacturing, operation, office, and pilot plant in Overland, Missouri. Provided initial facility for Air-Pallet® Container assembly, manufacturing of filling and unload systems for the Air-Pallet® container, and expanded pilot plant for testing and demo of a large range of powders. The Company moved to an expanded 65,000 square feet manufacturing, office, and pilot plant facility at current location in Fenton, Missouri. Provided additional space required for manufacturing of process equipment, pilot plant facility and expanded office requirements.

1996-2016 – Semi-Bulk 2.0

1995: Decision was made to reduce emphasis on air-pallet container business and increase emphasis on process business and sanitary markets versus industrial markets and products. Adopted manufacturing practices related to 3A Sanitary Fabrication. Began developing processes related to sanitary handling of powder and processes related to powder/liquid mixing.

Mr. Handleman retired from Semi-Bulk Systems in 1996 shortly after the formation of the Semi-Bulk Systems Sanitary Division (food, dairy, beverage, cosmetic and pharmaceutical) in 1995. Mr. Ronald Bentley was named Director of the new division. The VACUCAM® (VACUUM Convey and Mix) Slurry Processes were expanded to offer both the food and industrial markets this state-of-the-art technology for mixing powders and liquids.

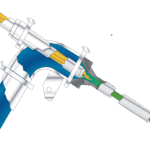

Although systems were previously sold for such processes, the company began to focus on these hygienic processes for dry powder handling and powder/liquid mixing. To support and promote the VACUCAM® Slurry Process Technology, Semi-Bulk’s product lines were expanded, adding many new products to meet the requirements for hygienic processes. These new product lines were developed to offer a TOTAL SOLUTION, including dry side modular processes with Air Cone ® Hopper (ACH) and powder/liquid mixing modular processes based on Vacucam® Ejector Mixer (EJM) and full solution standardized modular skidded powder mixing processes.

The products developed to focus on conditioned powder feed included bulk bag unload stations, bulk bag unloaders with surge bins, hygienic design Air-Cone® Hoppers and many new modular processes.

With the achievement of ISO 9001 and 3-A Certification as well as sanitary fab transition, Semi-Bulk Systems expanded into new food, chemical and industrial markets including dairy, beverage, sugar, power plants, paint and others serving both smaller operations as well as Fortune 50 manufacturers.

At the same time, Semi-Bulk Systems began expansion of distribution outside the United States into Europe, Mexico, China, Asia, Brazil, Japan and India.

1997: Introduction of the first bulk handling Sugar Liquefication process designed to vacuum convey sugar from bulk truck unload with water on a Continuous Steady-State (on-demand) basis. Used for handling large volume ingredients. Original installations with U.S. ice cream facility.

1998: Company achieved ISO 9001-1994 Certification. SBS currently holds ISO 9001-2015 Certification. Provided credibility and capability to increase emphasis in manufacturing for sanitary processes and projects through major engineering houses.

2000: Introduction of the EJM 2000 Inline Mixing Skid unit designed to vacuum convey conditioned powder from various powder sources, mix powder with liquid media on a Single Pass or Batch Recycle basis. Used for handling most medium volume ingredients, including those with higher solids. Original installations within various U.S. based paint and cheese facilities.

2004: Introduction of the Mixer-on-Stand (MOS) unit specifically designed for optimum dissolution of thickeners, gums, dairy protein powders, and sensitive ingredients, typically lower solids (<20-30%). Original installation at a paint plant in Sweden.

2012: Established representative presence in China as well as expanded presence in multiple paint plants in China and additional systems with international paint plants in multiple Asian countries.

2016 – Present – Semi-Bulk 3.0

The company’s products have always strongly supported industries’ initiatives to develop sustainable processes. From the support of the wildfire chemical business for fighting wildfires around the world, to providing the industrial and food process industries with process solutions to reduce energy consumption and provide major Process XstreamLining® benefits, the company’s technology and process solutions continue to provide opportunities to allow customers to improve their product quality, meet capacities and achieve lowest cost production while meeting or exceeding their sustainable objectives.

- Company focus-powder handling & powder/liquid mixing processes –THE TOTAL PROCESS SOLUTION

- Technology – dry side modular processes w/ ACH including PH& BBU product line; powder/liquid mixing modular processes based on EJM

- Build brand to promote and recognize Technology benefits vs. Traditional processes —Process XstreamLining®

- Product lines – dry side standardized modular components; standardized modular skidded powder mixing processes

- Distinguish Engineering & Fabrication Standards for Sanitary vs. Industrial Projects.

2016: Established presence in India with major paint company. Expanded partnerships and presence in India, China, in Italy for Europe, and in Chile for South America.

2018: Installed pilot plant in Milan, Italy.

A History of Quality

The company’s products have always strongly supported industries’ initiatives to develop sustainable processes. From the support of the wildfire chemical business for fighting wildfires around the world, to providing the industrial and food process industries with process solutions to reduce energy consumption and provide major Process XstreamLining® benefits, the company’s technology and process solutions continue to provide opportunities to allow customers to improve their product quality, meet capacities and achieve lowest cost production while meeting or exceeding their sustainable objectives.

If you need technical support, please contact us at 651-653-5098.

Semi-Bulk operates in Maplewood, MN to both demonstrate our Dynamic Dispersion Technology as well as to conduct actual testing of customer products. We will also conduct trials with our equipment in the customers’ facility. Leasing and rental options are also available.

Customized Process Xstreamlining Solutions

Semi-Bulk Systems, Inc. is considered a true partner in developing specific processes customized to maximize competitive and profitability positions. Our patented processes; our modular skidded approach to provide a Total Solution for both dry side and dry/liquid mixing; and our focus on providing major benefits vs. traditional processes have revolutionized the markets we serve including Beverage, Dairy, Food, Health & Beauty, Paint & Coatings, Paper, Power Generation, Chemical Manufacturing and more!

Do you need process improvement to increase efficiency, lower process costs, save labor costs, and increase your bottom line? Our Process XStreamlingsm solutions can help you accomplish these goals.